Lean

Six Sigma, when is it time for change?

Anybody who has worked in manufacturing or

in the back-office will know some process; action or event could have being done better! Whether it’s small or large in our company,

we rarely see timely change happen as a result of our idea creating value in

higher productivity, lower costs or both! Sustainable

Capitalism has evolved out of two main elements, the need for an ethical

working conscience and the need for productivity driven value creation that

aids innovation and growth in a socially aware manner. This in effect makes

monetisation a consequential priority for if we develop products for market in

a socially aware manner and deliver productivity solutions through top tier

process management; our ability to make money is practically

guaranteed.

So why does the idea of shortest path

travelled to monetisation which can include process circumvention hold such

allure for senior executives in planning sessions and indeed on a day to day

basis? In my view, I think the following three elements are key in driving this

short-term view especially in western business culture.

- 1. The quarterly culture especially in “plc.” registered companies tends to put priority emphasis on shareholder value and cash positions in the deliverance of results. These priorities sit on the throne of perceived value alongside profitability even if it’s at the expense of one or all of them into the longer term.

- 2. The “treadmill effect” has being noted by some analysts as being a driver of irrational decision making in operational strategy where market demands fed by management’s exceeding of prior quarterly expectations demand the improbable which management set out to deliver at the expense of future longer term sustainability

- 3. The “strategic planning cycle” in western business culture is rarely beyond 5 years and most senior executives are incentivised solely on their performance within this short to medium term period. The incentive to think beyond this for senior executives is for the most part not in place creating a short term planning culture, which only includes executive considerations that don’t exceed the cycle period.

There are more elements, but in my view,

the above three are the most impacting and illustrate how understandable it is

for many managers to not embrace sustainable capitalism’s need for longer-term productivity

when priorities lie elsewhere. That said, there are competing schools of

thought where value creation through efficiency and cost effective process

management add value and years to a

company’s lifecycle which has made companies like Toyota and IBM the

evolving success stories they are today. The ideas are a fascinating evolution

from the Kaizen

continuous improvement methodologies originating in Japan approximately a

hundred years to Toyota’s improved Kaizen system of materials handling to Six Sigma; then to

Lean

Six Sigma.

You would rightly say at this point “wow,

great story but what has it got to do with my company and real life?”… Good

question! Toyota, IBM and all the pioneers of six sigma have come up with

the same statement as we invariably have in the course of our careers, which is

“what can we achieve through making our processes better that would delight our

customers, whilst increasing productivity and reducing costs?” The backdrop to

this question has nearly always being high costs, low quality outputs and

cumbersome processes driven by an organic evolution of process. The temporary

nature of this shorter term focus has allowed in my view process inefficiencies

to aggregate over time into company wide threats, which in turn has given rise

to responses like Six Sigma and Lean Six Sigma with its company wide solutions.

Lean Six Sigma has a structured and logical

approach for both physical processes (Six Sigma) and services (Lean), which see

an evolution of thinking in process improvement through some highly effective

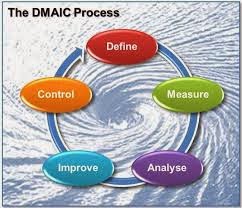

tools like the “DMAIC” process.

· Define the process as it is

·

Measure the process in quantitative

terms using metrics to capture the value creation elements of the process

·

Analyse the causes of the problem

inhibiting process productivity and/or high associated costs

·

Improve the process design to address

the identified issues restricting value creation within the process

·

Control the process through revised

metrics including lead

and lag controls within the process structure which will measure the

improved state of the process ergo ensuring value creation from process

improvement.

Lean process management focuses on the

amount of value creating steps it takes to complete a process, which has had a

huge impact on customer facing services in particular where one process can

replace many and a customer’s actions within the process are reduced to a bare

minimum. Lean is based on the assumption that waste in business is toxic to its

sustainability and thus should be eliminated based on the following process:

- Application*. Define the process focusing on where the value is for the customer.

- Identify Value Stream*. Define the steps within the process that add value and those which do not. Adding value can be direct or indirect in relation to the customer.

- Make It Flow*. Ensure the process has a continuous movement with appropriate controls such as lead and lag to create and measure value creation in the process flow.

- Let Customer Pull*. Ensure you don’t over supply to your customer demand. Customer demand should be a trigger for production and service provision.

- Pursue Perfection*. Under the high bar of continuous improvement, there is no limit to process value creation and no ceiling of perfection.

With lean, the key is continuous flow of

processes integrated in a demand driven process structure that allows the

shortest effective process time line between process start and completion points

increasing productivity and reducing costs as all non value creating steps are

exited from the revised process.

With Lean Six Sigma, the combining of both

methodologies in a company wide structure enhances the integration of effective

internal process structures that increases productivity, decreases costs,

increases output quality and resulting customer satisfaction. It also allows a

company access to flexible control tools and information that empowers

management and employees to pursue sustainable capitalism in a productive, cost

effective and socially aware manner.

When we look at Lean Six Sigma, the

concepts of high process quality leading to high outputs are braced in its

scoring as follows:

- · 2 Sigma = 308,537 (69.15% productivity yield) faults per million

- · 3 Sigma = 66,807 (93.32% productivity yield) faults per million

- · 4 Sigma = 6,210 (99.38% productivity yield) faults per million

- · 5 Sigma = 233 (99.98% productivity yield) faults per million

- · 6 Sigma = 3.4 (99.99% productivity yield) faults per million

Its not hard to see the qualitative aspects

of Six Sigma’s scoring system and how qualitative process design based on the

value creation aspects of the process is so important for a companies success

and sustainability over time.

As a practitioner of lean process management for over a

decade, I feel that the birth of Lean Six Sigma is the next platform of

process greatness bringing greater value to many facets of a company’s operation.

That said, it is still a platform and from my own experience in process

management, I would advise the following to anybody engineering, re-engineering

or developing a process platform using Lean Six Sigma or any logical form of

process management.

- · Contextualise your process design ideas into your operating environment, established business practices, the company culture, 3rd party business partner relationships and their internal culture(s) to understand what works, what doesn’t and how it all interacts with each other.

- · Never forget your customer. The internal customers (other business units/colleagues) can become higher priorities when conducting an internal process review. It is therefore easy to forget the external customer who pays your invoices and funds your ability to conduct what very same review. Lean process management is about leaning into the customer and understanding how their needs and wants impact your process and vice versa.

- · Process effectiveness requires understanding of what the desired outcome of the process actually is, where waste occurs and addressing the ineffective steps by withdrawing them in favour of what is effective to the desired outcome of the process. Above all, the process has to be contextually inset into the overall process structure and be flexible enough to handle the commercial needs of the organisation where outlier cases can be processed reasonably in a controlled manner through an established and integrated process structure.

We all strive to eliminate waste from our

company and drive a better process environment. I submit that the time is now as

we enter an upward economic trajectory to reposition our companies to a more

sustainable footing using tools like Lean Six Sigma to evaluate ourselves

internally, make the changes to business practice, attitude and approach, which

in turn allows us to drive forward with confidence in our ourselves, our

colleagues and our future. We can then see process greatness enable flexibility

along with longevity in our partnerships with employees, business partners,

customers and wider society for many years to come.

Nice observation and thinking as well but you can make this more beautiful if you ever try to increase you knowledge, if I give some suggestion you must visit for Kaizen Training. Good effort dear.

ReplyDelete